Multi-Point Inspections (MPI)

The MPI Inspection Process

A step-by-step guide from the Advisor to the Technician on the Multi-Point Inspection (MPI) Process. This workflow ensures that all findings are clearly documented, accurately coded, and visually supported if necessary.

MPI Workflow:

The Technician must have an Operation assigned on the Repair Order to access the MPI/MPVI in the Technician System, and the RO must also be released by the Advisor so that the Technician can access the RO.

Once an operation is assigned and the RO is released, the Technician will log in through the Tech system: Service>Technician>Technician System, Select RO, Select MPI/MPVI.

The MPI/MPVI loads:

Clicking the Green indicator marks the item as OK. Checking the Yellow or Red Indicator opens a pop-up to add an Op-Code, Concern, Correction, and the ability to take a picture of the issue:

- When a Technician selects a yellow or red item, the pop-up allows the technician to enter a Concern and Correction.

- Type in concerns and corrections or select preset concerns and corrections.

- If the Technician doesn’t have time to select a preset or type in concerns/corrections, they can click on [Save] and a default concern will automatically be added.

- Take a photo of the vehicle if needed for the Advisor to share with the customer by clicking [Take Photo]. The image will then be saved in the Photos.

-

Click [Save] when the task is completed. Save at any time throughout the process in case of interruption.

-

Once saved, select [Mark as Complete]

- A notification is sent to the advisor, and A PDF is attached to the Repair Order that can be emailed, texted, or printed to review with the customer.

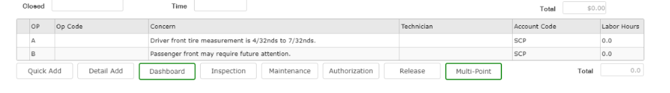

At the bottom of the RO, the Multi-Point button is highlighted in green to indicate the MPI/MPVI has been completed.