Excessive Bin and Negative On-Hand Report

Identify Excessive and Negative QOH Inventory

The Parts Manager uses the Excessive Bin and Negative On-Hand Report to identify and summarize inventory items in a dealership’s parts department that either exceed their designated maximum bin quantities or have a negative on-hand quantity.

Frequency: Daily, Weekly, and Monthly

How It’s Used

- Inventory Control: It lists all parts where the on-hand quantity (OHQ) is negative, meaning the system shows fewer items in stock than zero. This can indicate issues such as data entry errors, unprocessed receipts, or inventory discrepancies.

- Order Management: The report excludes parts where the “on order quantity” (OOQ) is enough to offset the negative quantity. In other words, it only shows items that remain negative even after considering incoming orders.

- Audit and Correction: Used by inventory managers to audit stock levels and correct errors in the system.

- Spot Excess Inventory: The report lists parts where the on-hand quantity (OHQ) is greater than the maximum allowed for each bin.

- Support Inventory Management: By highlighting overstocked items, the report helps parts managers make decisions about transferring, returning, or discounting excess inventory to optimize stock levels and reduce carrying costs.

Navigate to: Parts > Reports > Audit> Excessive Bin and Negative On-Hand Report

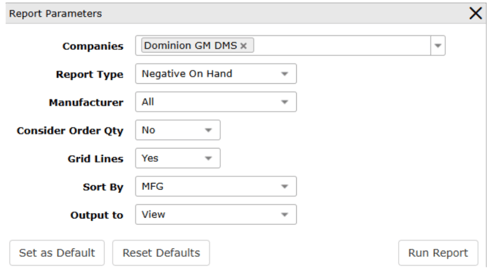

Choose Parameters

This section clarifies the parameters outlined in this report. For additional details that apply to all reports, please refer to the Common Report Features article.

Report Type:

-

Excessive Bin

-

Negative On Hand

-

Both

Consider Order Qty:

-

No: Results will display all part numbers with an on hand quantity that is less than zero

-

Yes: Results will display any part numbers where Negative On Hand + On Order Qty = (0) zero or more

Example 1: Will not be on the report

-

On Hand is –2 and On Order is 3

Example 2: Will be on the report

-

On Hand is –2 and On Oder is 1